STEAM FLASH TANKS

Flashing High Pressure Condensate into Steam

![]()

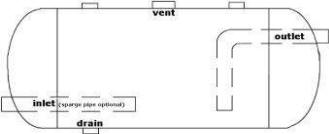

Flash tanks safely convert high pressure condensate into quality (drier) lower pressure steam and condensate. Usually condensate temperatures within high pressure steam are slightly less than the saturation temperature, thus when it is discharged into a lower pressure area (flash tank) some of that condensate instantly converts to steam. A flash tank therefore separates the lower pressure steam from the condensate. The low pressure steam can be vented though an exhaust head to the atmosphere, used for other processes such as heating and to reduce and cool low pressure steam before it is returned to the boiler, condendate receiver or discharged to sewer.

Our flash tanks are designed in accordance with ASME Code Section VIII, Div. 1 and can be ASME Code Stamped for 150 psig steam service; higher pressure rated vessels can be supplied upon request. Most flash tanks are manufactured from carbon steel however other alloys can be used for aggressive environments.