Separation Capacity of Centrifugal Gas/Liquid Separators

Sizing Gas/Liquid Separators When the Rate of Entrained Liquid is the Driving Factor

Call us at 908.362.9981 to speak with a sales engineer

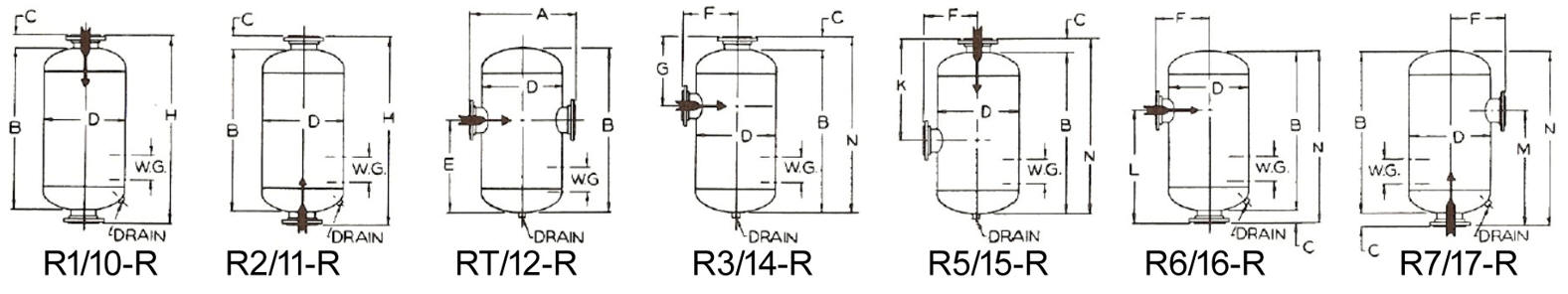

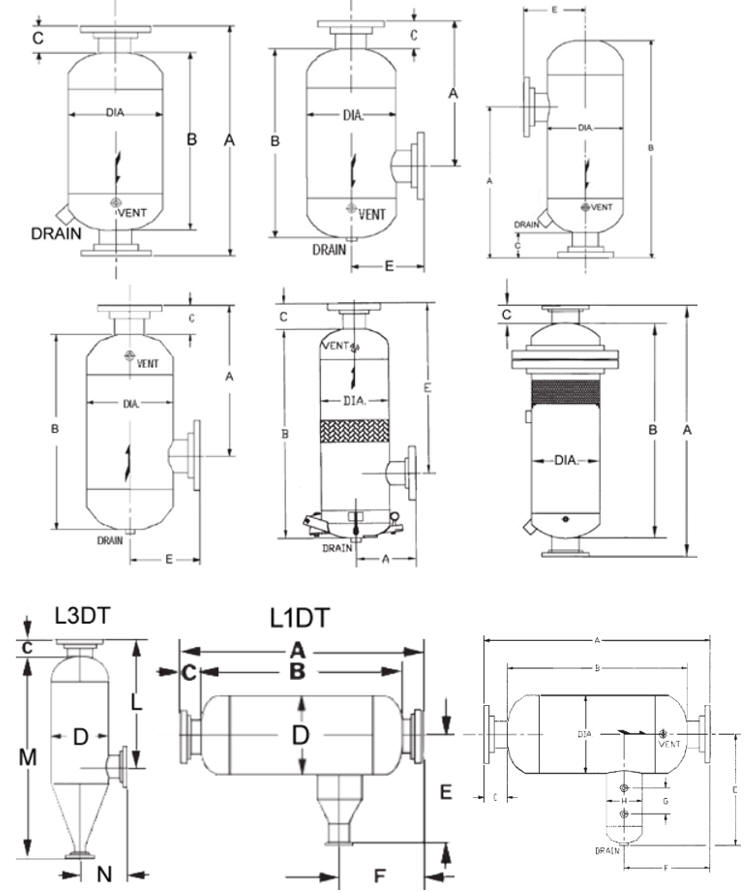

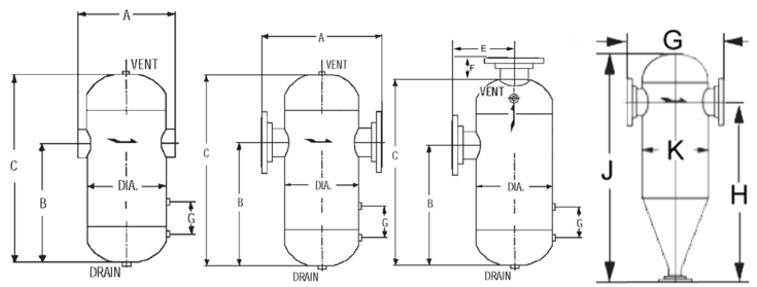

This article provides an overview of the 28 centrifugal gas/liquid

separator models as relates to our online separator sizing calculators.

Sizing

Program

Sizing

Program

-

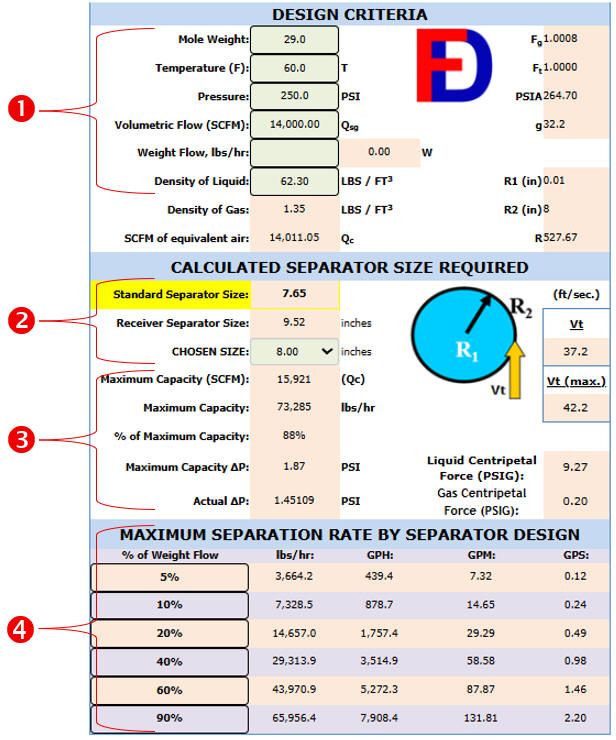

The first section is the design criteria to input, notably input the molecular weight of the gas, maximum temperature, minimum pressure at which to maintain separation efficiency and maximum flow rate for the application. If a reciprocating style compressor is delivering the flow, double the flow rate to ensure proper sizing.

-

The minimum separator size required is calculated for two types: standard and receiver style separators. Note “size” is an indirect reference to the minimum vessel diameter and cylindrical length of the separator body. Separator sizes are based upon the maximum allowable inlet nozzle ID and provides an easier way to compare different separator designs. Input the “chosen separator size” ≥ the calculated separator size required to review its performance.

-

The performance data for the chosen separator size based upon the design criteria (1). The data includes maximum vapor capacity (volumetric and mass), the percentage capacity used based upon size chosen and the differential pressure for both maximum capacity and the design criteria. If your application has maximum differential pressure threshold, you may need to increase the separator size until you satisfy that design criteria.

-

Table of maximum liquid separation capacity in mass and volumetric units based upon the six possible separation capacities (capacity is separator model dependent). These capacities help you compare between designs, for example using a design which has a 60% separation capacity compared to a larger size based upon a 20% or 40% design.

Maximum Liquid Separation Capacity

The maximum

capacity for a given size gas/liquid separator is dependent upon the

operating pressure; at higher pressures the capacity increases. The

maximum liquid separation capacity is expressed as a percentage of the

maximum vapor flow rate capacity for a given set of design criteria, but

mostly the lowest operating pressure at which maximum separation

efficiency is required. In above example the 5% - 90% table data are

with reference to a maximum vapor capacity of 73,285 lbs/hr.

Performance

Separation efficiency for single stage

gas/liquid separators is separation of entrained droplets > 10 microns

in diameter with 99% efficiency. Dual stage (coalescing) separators may

separate droplets as fine as >0.3 microns in diameter with 99%

efficiency.

Specialized Designs

Some

separator models are designed for specific application characteristics

which range from separation of liquid “slugs” to separation of viscous,

slurry or high particulate vapor flows.

CLICK THE PICTURE TO VIEW CORRESPONDING

DATASHEET

5% Separation

Models: 31L/36L

The maximum liquid separation capacity for

these designs is equivalent to 5% of the maximum rated capacity.

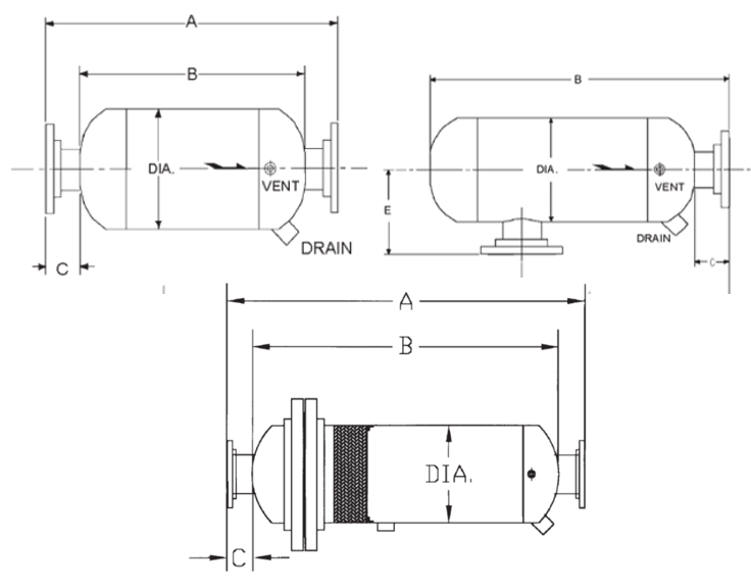

10% Separation Models: 32L/34L/37L/EH

These

separator designs have a separation capacity equivalent to 10%.

20% Separation Models:

31L/S, 33L, 35L, 36L, DTL,

35L/36L

There are several separator designs which have a separation

capacity equivalent to 20%, including coalescing and clog resistant

versions.

40% Separation Models: T, TT, DT (clog

resistant)

These separator designs have a separation

capacity equivalent to 40% of the maximum capacity of a given size

separator.

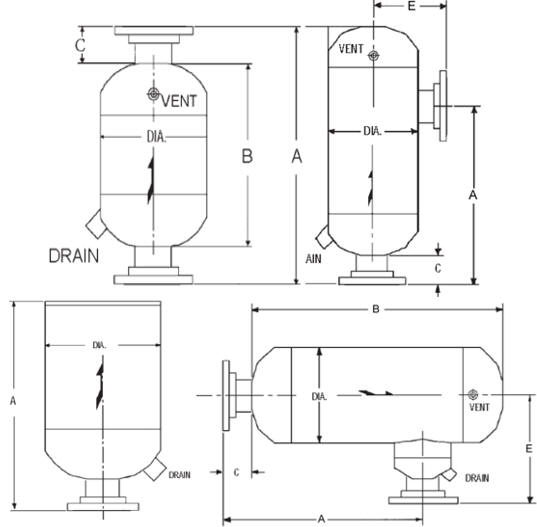

60% Separation Models:

The type

TS separator has a separation capacity equivalent to 60% of the maximum

capacity of a given size separator. The type TS is based upon a type T

design (40%) except it has an elongated body to increase separation

capacity and has a hold-up volume to support drainage via specialized

valves or pump systems.

90% Separation Models:

This design is referred to as a “receiver separator” and has a

separation capacity equivalent to 90% of the maximum capacity of a given

size separator. As reflected in the sizing calculator a larger separator

body size is typically required for such a high liquid separation rate.

Continuing with our example, an 8” size separator is sufficient for the

design criteria but a 10” size is required if using a receiver separator

deign. This is due to increased internal complexity required to achieve

high liquid separation rates.

When the liquid entrainment rate is

the driving factor for separator sizing, often receiver separators will

provide separation in the smallest physical “footprint” when compared to

“oversizing” other separator designs.

Related Articles