Comparison of Float Drain Trap and Inverted Bucket Trap Designs

Call us at 908.362.9981 to speak with a sales engineer

The removal of entrained water within steam

processes is essential to recover energy, protect downstream equipment

and enhance a process. Drain traps play an integral role in removing

condensate from piping systems without loss of steam. Two of the most

common drain traps used in piping systems are float drain traps and

inverted bucket drain traps. These mechanical valves operate on similar

principles however, they are used for different applications. This

article compares and contrasts both designs in detail.

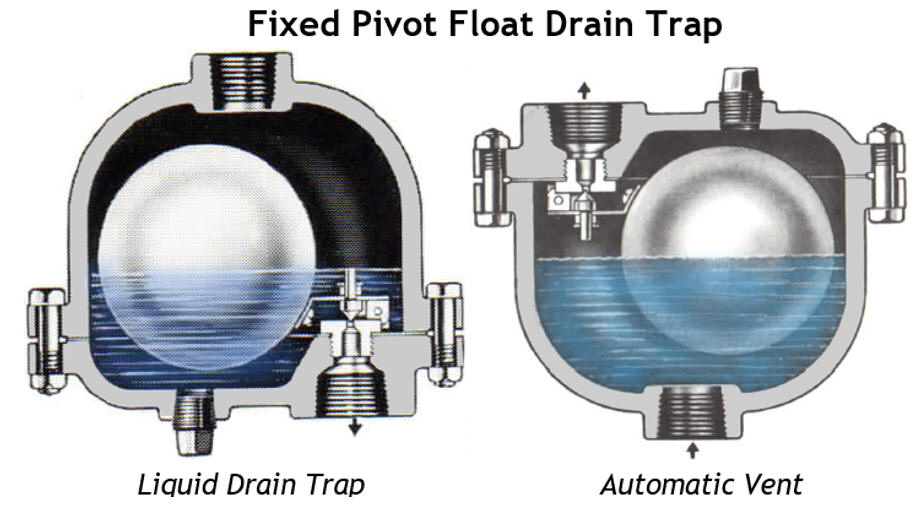

Float

Drain Traps rely on the buoyancy of an internal, weighted float to open

the valve and allow drainage of liquid once the trap body becomes

sufficiently filled with liquid. The standard buoyancy of the float is

calibrated to the specific gravity of water and thus functions well for

water-like liquids; its buoyancy can be modified by adjusting the weight

within the hollow float for use with other liquids.

Some float

drain traps have a top-side inlet and a bottom-side outlet so that when

the trap is installed at a low point in the system where liquid will

accumulate, it gradually fills the trap body while any entrained air or

steam percolates upward and back into the system via the traps inlet

port. In cases where a float drain trap has a side inlet or is not

directly below the liquid source, a vent port on the drain trap is used

to vent air and steam back into the system, preventing vapor lock of the

valve/float assembly.

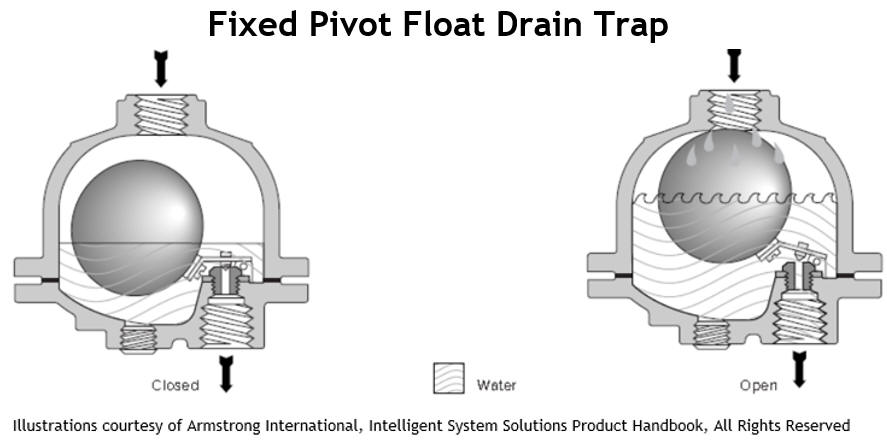

Fixed pivot style float drain traps connect the

float to a fulcrum/lever/valve assembly such that when there is

sufficient buoyancy of the float, the valve is lifted off its seat and

liquid drains though the seat orifice at a rate based upon the diameter

of the orifice and differential pressure of the system pressure vs.

atmospheric pressure. There are several seat orifice diameters to

accommodate drainage rates sufficient for the system while minimizing

the number of closure cycles and corresponding valve/seat wear.

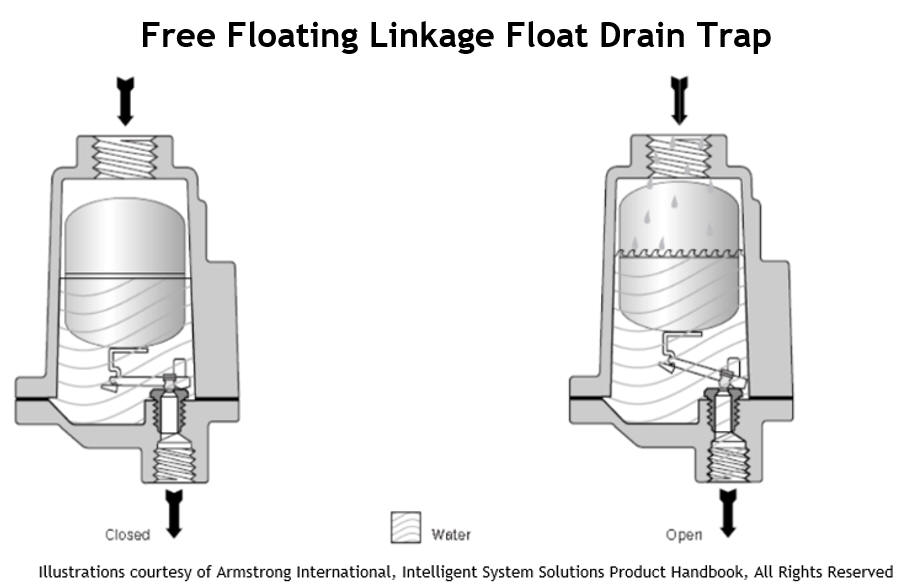

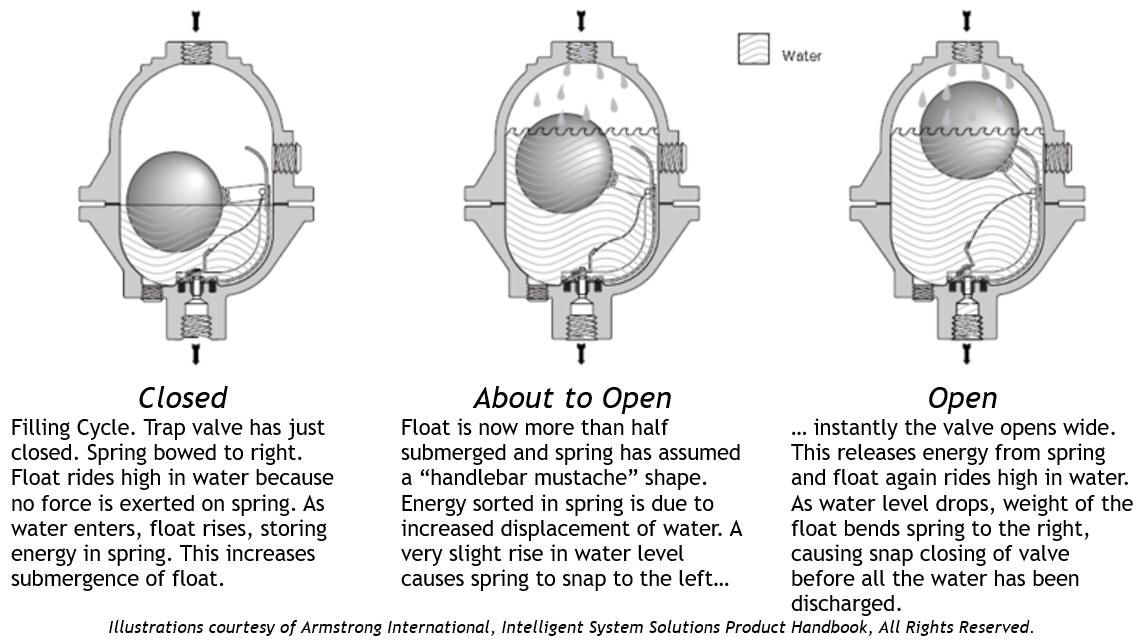

Free floating linkage and snap action float drain traps are variations

which operate on the same principle but offer advantages in some

applications. A free-floating linkage between the lever and valve

improves the seal against the seat and a snap action style lever ensures

the valve is 100% opened when draining liquid to minimize potential for

clogging the seat orifice.

Key characteristics of a float style drain trap

is that there is always a liquid barrier or seal between the process gas

and drainage, thus when installed where freezing is a concern, a heater

must be installed or the trap needs to be insulated. Float drain traps

do not need to be primed with liquid and they should be periodically

drained via their body drain plug to purge the trap body of any material

that settled within the trap housing such as pipe scale or rust.

Advantages of float drain traps are that they eliminate steam loss

during drainage and they are very reliable due to their overall

simplicity. They can also be used for non-steam applications (compressed

air and other industrial gas systems) to drain entrained liquids because

you can adjust the weight of the float for liquids having extremely low

or high densities. The standard float weight will work for liquids

having a specific gravity as low as 0.40. They can also be used to

separate a heavier liquid from a lighter liquid and as air vents.

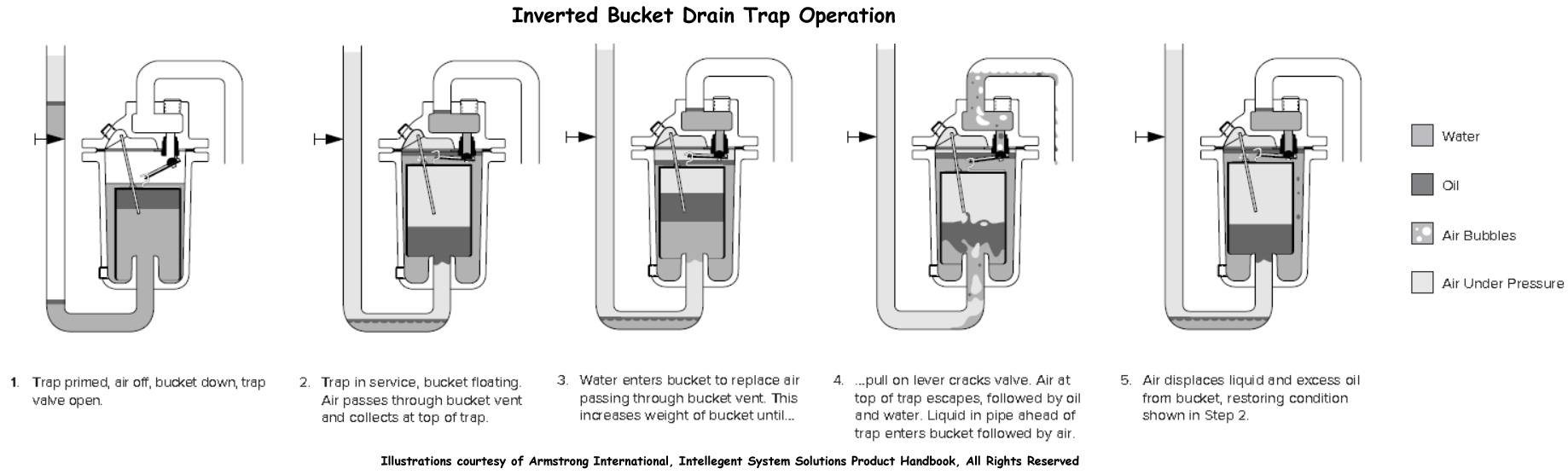

Inverted Bucket Traps also operate on the

principle of buoyancy although their mechanical design is more complex

than a float drain trap. Inverted bucket drain traps are mostly used in

steam systems although they can be used in compressed air and industrial

gas systems

The two major components of an inverted bucket drain

trap are the trap body and the internal “inverted bucket”. The flow

pathway is through a tube at the bottom side of the trap body protruding

into the inverted bucket.

At the top of the inverted bucket is a

vent orifice and linkage attached to a plunger and seat. When the bucket

loses buoyancy, the valve is pulled away from the seat and the system

pressure pushes condensate through the seat orifice.

Initially

the trap body and bucket are filled with water, this is referred to as

“priming the trap”. Its purpose is to ensure a liquid seal at the valve

seat orifice and a non-buoyant bucket.

As steam and condensate

enter the trap, it is directed into the inverted bucket; the vent port

allows air and other non-condensable gases to vent to an area above the

inverted bucket. Once sufficient steam accumulates within the bucket, it

becomes buoyant and closes the drain valve. As the steam entrapped in

the bucket condenses into condensate within the bucket, the bucket loses

buoyancy, causing the valve to open and entrained liquid and air to

drain from the system. The volume of condensate purged is equivalent to

the volume of steam required to create buoyancy, which is approximately

1/3 the volume of the inverted bucket.

When used in a compressed air or other

industrial (non-condensable) gas system, the gases which accumulate at

the top of the inverted bucket are vented back to the system piping.

Advantages and Considerations:

Float drain traps

offer advantages such as zero steam loss during drainage, simplicity,

and reliability. They can be adjusted for various liquid densities and

used for non-steam applications like compressed air systems. In

contrast, inverted bucket traps are more adept at handling heavier oil

contamination due to gravity-assisted drainage. They are especially

effective in steam systems and can be used for industrial gas systems.

Both designs require periodic maintenance to remove contaminants,

and heavy oil loading can impede their operation. Float drain traps are

available in a wider variety of materials, can handle higher pressures,

and accommodate higher liquid loads compared to inverted bucket drain

traps.

Fixed pivot style float drain traps have an additional

application as a high capacity air vent. When installed inverted, the

valve remains open to vent gasses and automatically closes after the

body is filled with liquid, causing the float to rise and close the

valve orifice. Air vents are used to assist with pump priming and at

high points in piping to reduce the amount of entrained air or gas in

the system.

In conclusion, while float drain traps offer

simplicity and reliability, inverted bucket traps excel in managing oil

contamination and recovering steam. The choice between the two depends

on the specific requirements of the application. Whether it's steam or

compressed air systems, selecting the right drain trap is essential for

efficient condensate removal and system performance.

Let us put

our 33 years of experience to work for you, think of Factory Direct

Pipeline Products the next time you have a

requirement for a liquid drainer!