Internal Baffle Assembly for Centrifugal Separators

![]() Separator element

specifications

Separator element

specifications

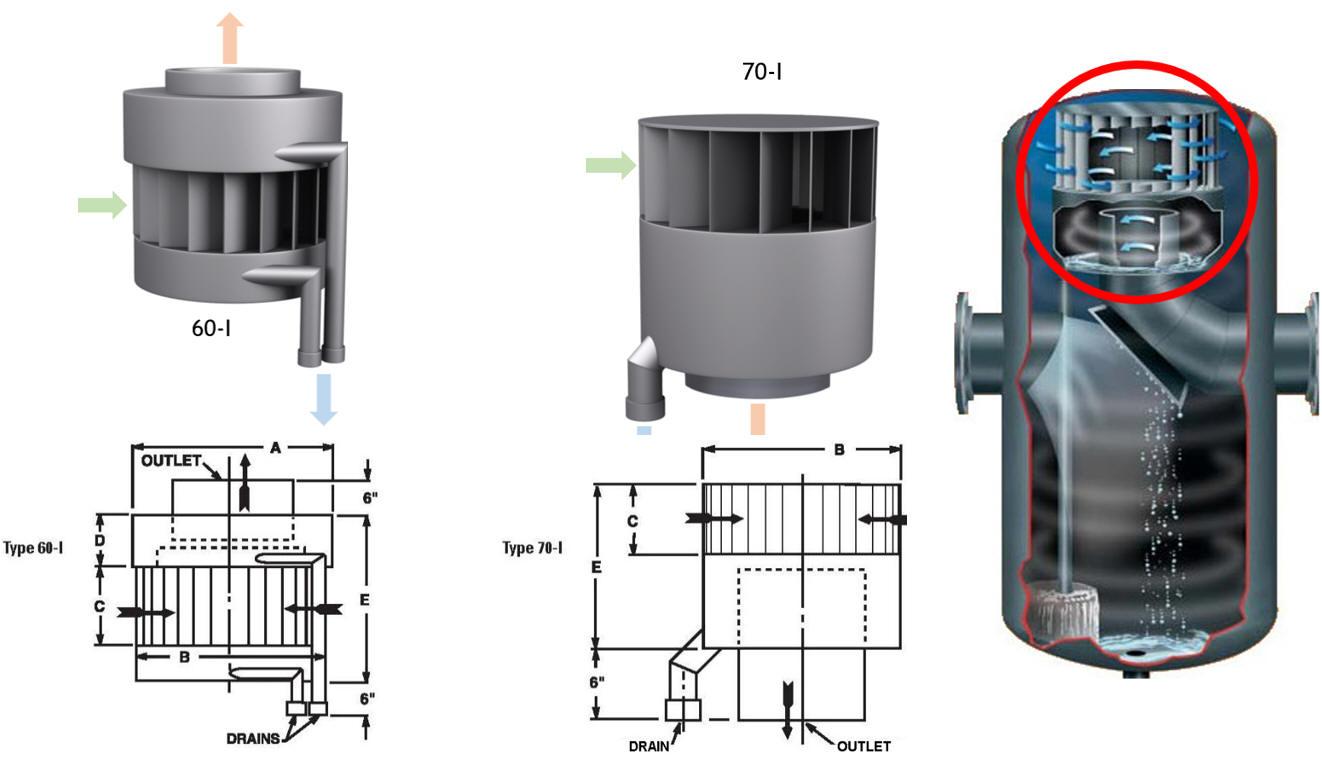

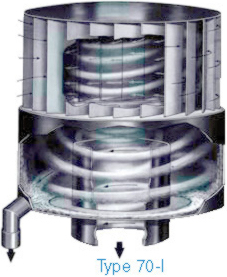

At the heart of centrifugal separators are the internal elements or

baffles which create a complex pathway that droplets and particles

larger than 10 microns cannot pass through without impinging upon.

Thus separator elements must be sized large enough to handle the process

flow rate without much of a pressure drop as well as having the

capability to drain the liquid load quick enough.

At the heart of centrifugal separators are the internal elements or

baffles which create a complex pathway that droplets and particles

larger than 10 microns cannot pass through without impinging upon.

Thus separator elements must be sized large enough to handle the process

flow rate without much of a pressure drop as well as having the

capability to drain the liquid load quick enough.

Properly sizing an element involves using only 65% of the equivalent air

or steam flow based upon our capacity charts and calculators.

Non-air gasses need to be corrected to their equivalent air flow

when using the sizing chart; our calculator will automatically do this for you.

To calculate the minimum distance from the bottom of the element to

the surface of the liquid add 12" to the pressure drop across your

vessel in inches of water.