Gas Liquid Vortex Separators

Centrifugal droplet separators for industrial gasses

Call us at 908.362.9981 to speak with a sales engineer

Chemical manufacturers routinely process oil, natural gas, air, water

and minerals into products consumed directly or as a component of an

additional product or process. Gasses are processed at various

pressures and temperatures (dew points) to purify and refine the desired product.

These processes often benefit from removal of entrained droplets and

particulate for the same reasons vortex style separators are used for

steam and compressed air systems. Sometimes the liquid and

particulate removed ARE the desired product.

The majority of our

customers consist of Earths largest chemical manufacturers and we have

worked directly with plants in at least 66 countries solving liquid and

particle entrainment applications. Our customers include:

It is commonplace for vortex separators to be designed to handle atypical temperatures,

pressures and aggressive chemistries which require using exotic alloys.

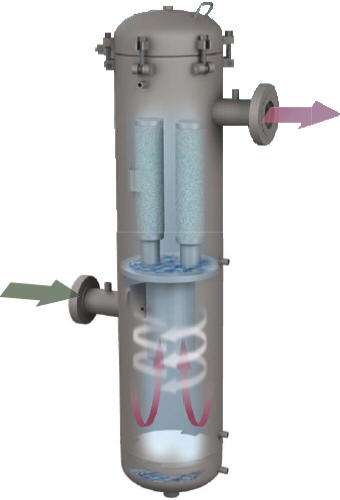

How Centrifugal Separators Work

How Centrifugal Separators Work

Vortex separators rely on centrifugal force, reduction in velocity

and torturous paths to remove droplets and particulate greater than 10

microns with 99% efficiency from the gas stream. Multiple stage

designs are available to reduce the droplet size removed to as low as

0.30 microns.

Infinite Turndown Ratio

Vortex separators have an infinite turndown ratio,

which means that a reduction in centrifugal force resulting from reduced

flow does not reduce their efficiency. The reason vortex

separators maintain their efficiency at low flows is due to the greater

reduction in velocity associated with lower flow rates.

The

internal baffle geometry is oriented at right angles to the inlet of the

vessel and thus droplets with sufficient mass cannot "navigate" through

the baffles without impinging on or within the baffle assembly.

All of the droplets and particles coalesce from the baffle and interior

walls to a common drain. Therefore the vortex separator vessel and

internal baffle are sized to handle the design liquid load as well as

ensure minimal pressure drop across the vessel.

Vortex separators

are custom fabricated to your specific application requirements which

includes the rate of liquid removal required, material of

construction, number of nozzles and their orientation, plus design

pressure and temperature. We can comply with special NDT/NDE/Coatings

and special documentation requirements. All of our centrifugal vortex separators are

fabricated in accordance with ASME B and PV Code Section VIII Division 1

in compliance to current published addenda and may be U or UM stamped.