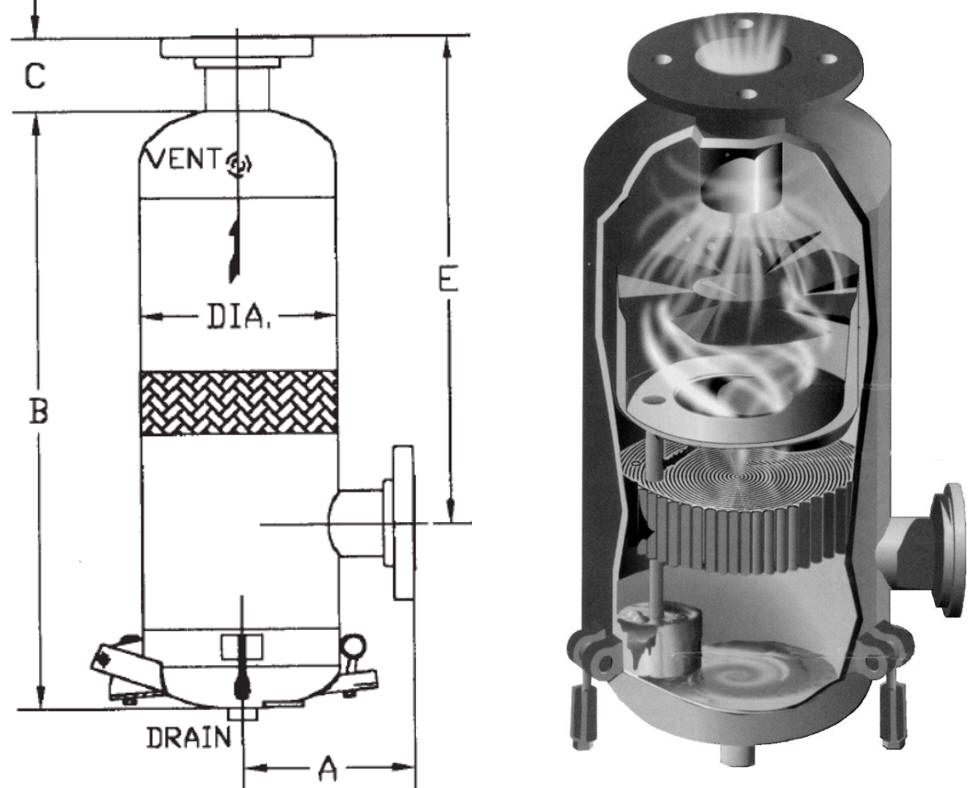

TYPE 35L-CLC/L5C COALESCING GAS-LIQUID SEPARATORS

Droplet separators 99% efficient for droplets >10 microns

![]() 35L-CLC (L5C)

separator specifications

35L-CLC (L5C)

separator specifications

Fully welded pressure vessel fabricated to ASME Code Section VIII Division 1 with stamp, has no serviceable/moving components, requires zero maintenance. This is a two-stage design with the 1st stage coalescing droplets larger than 5 microns in diameter into droplets larger than 10 microns in diameter with a coarse mesh pad. The 2nd stage is per the standard design where the combination of indirect pathway, inertia and gravity separate droplets larger than 10 microns in diameter with 99% efficiency. This separator design is more costly than a standard 35L/L5 design due to the flanged body, a requirement in case the mesh pad requires cleaning or replacement.