Gas-Liquid Separator Applications

The ultimate self-cleaning filter

Call us at 908.362.9981 to speak with a sales engineer

Think of a centrifugal gas/liquid separator as a type of non-mechanical,

automatic, self-cleaning filter for gaseous applications. They are

designed to remove entrained particles and droplets larger 10 microns

with 99% efficiency with some designs capable of removing

particles/droplets as fine as 1 micron. Centrifugal separators are used

in a wide variety of industries and applications because the use of

compressed air, steam and industrial gases are ubiquitous to modern

manufacturing processes.

Following are examples of applications where centrifugal gas/liquid separators are used in power generation, environmental, food, electronics manufacturing, petroleum and chemical industries. While steam and compressed air systems are used in all of those industries, there are many applications for gas/liquid separation that involve process gasses.

Following are examples of applications where centrifugal gas/liquid separators are used in power generation, environmental, food, electronics manufacturing, petroleum and chemical industries. While steam and compressed air systems are used in all of those industries, there are many applications for gas/liquid separation that involve process gasses.

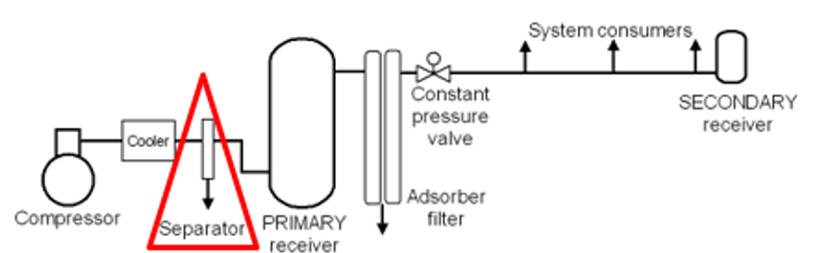

Compressed Air Systems

Air compressor systems take our natural air which contains moisture and particulates and condenses it under pressure to be used for drying, blow-off and instrumentation control device applications. When air is compressed the moisture forms condensate which mixes with any particles and tramp lubrication in the system piping. Large systems having complex piping and several low areas or several piping size changes enable build-up of liquid which is eventually swept as a �slug� downstream, reducing the effectiveness of drying processes, contributing to product contamination and damaging sensitive instrumentation � these are all reasons why centrifugal separators are used. Refer to our Air/Liquid separators for compressed air applications for additional information.

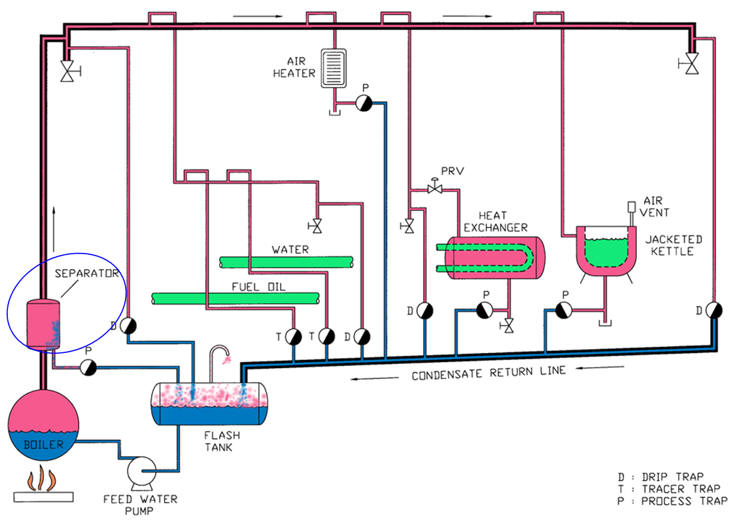

This is another type of application found throughout almost all industries because steam is used for heating, cleaning, atomization, humidification and propulsion. Many variables affect steam quality (the percentage of entrained condensate droplets within the steam). Generally, the further you get away from the boiler, the cooler the steam and more of it converts back to liquid water, which also includes corrosion inhibitor chemicals. Pipe scale and corrosion particles mix with the condensate and can clog or damage components downstream.

The nature of steam and compressed air systems is that they inherently create entrained liquid droplets in their piping, leading to corrosion and quality related issues. When combined with particulates in the piping, contamination, component damage and increased maintenance results. Centrifugal gas/liquid separators will separate droplets and particles larger than 10 microns with 99% efficiency, they are considered self-cleaning and never require maintenance. Physical dimensions of the separator and inlet/outlet orientation, material of construction and overall design confirm to ASME Code. Learn more about steam/condensate separators.

Food Processing

In addition to compressed air and steam system applications, there are many other applications that benefit from gas/liquid separation in food processing. One of the most common applications is to separate vented mist from mixing and tumbling vessels. Food products are sprayed with oils, flavorings, dyes, and sometimes cooled with water and then dried; coatings are controlled with high velocity compressed air or blower �air knives�. These types of processes generate mist which is source of product contamination and can reduce the efficiency of a heating or drying application.

Installing an exhaust head on the vent port of a pressurized mixing vessel helps keep the surrounding environment free from surface contamination, slippery surfaces and breathing in oil mist. In-line gas/liquid separators are used within vent systems in some processes to reduce build-up in ducting or reduce moisture prior to a combustion or gas treatment process.

Power Generation

Large-scale power generation systems heat water into steam which rotates turbine blades at high velocity. These blades are eroded from impacts of fine droplets, contributing to imbalance, which is amplified due to the high RPM of the blades. These turbine systems are very expensive to replace and down time equates to producing less energy, so it is paramount that they control the size and number of droplets through their system.

In addition to requiring high quality steam, many companies have incorporated turbine misting systems to increase the efficiency (horsepower) by as much as 15%. While there are many factors involved in generating a narrow histogram of fine droplets to be evenly dispersed within the intake piping of a turbine, a gas/liquid separator can be used to ensure the droplets exiting the separator are fine enough to pass through the turbine blades without damaging them.

Cogeneration is a type of process which uses biofuel byproducts to reduce raw energy requirements. An example is digester gas, a byproduct of municipal waste water treatment and when properly treated (removing of entrained liquid and particles) it can be used as fuel to reduce the utility costs of the treatment plants' dewatering process.

Petrochemical Industry

Such applications include refineries, natural gas processing, manufacturing of plastics and rubber - essentially products in which petroleum has been refined and used in their making. While we often think of petroleum refined into gasoline, there are actually many byproducts of the refinery process. These byproducts are created by controlling the pressure, temperature and injection of catalysts into liquids and gasses. In refineries there are many processes involving the compression and expansion of hot gasses, injection of chemistry and precipitation of the targeted byproducts. Some of these oils and solvents are used in the manufacturing process of other products.

Natural gas contains water, dirt and other impurities, some extraction methods result in more impurities than others (fracking). While settling tanks can be used to help separate gas from other liquid petroleum products and water, a separator at the wellhead is a compact way to separate entrained impurities larger than 10 microns, eliminating settling tanks which suffer from corrosion and damage from extremely low temperatures. When natural gas is transferred, it is typically under high pressure and thus additional separators are used to minimize corrosion and protect downstream equipment. View our webpage gas/liquid separators for natural gas applications for additional information.

Environmental

Liquids and particles which can be sent to atmosphere or ground are increasingly regulated; the EPA and local government agencies have established guidelines for disposing of industrial waste fluids such as compressor condensate and the tramp oils it may contain

Boiler treatment chemicals are carried-out through rooftop steam vents and can condense locally onto the rooftop itself or perhaps carry-on to nearby property and structures. Such carry-out is a form of pollution and results in an increased use of boiler treatment chemistry to make-up for what was carried out. Using an exhaust head, which is a centrifugal separator sized for atmospheric pressure, you can separate and collect the condensate for proper disposal or re-use.

Electronics Manufacturing

There are many chemical and physical processes required to turn sand into a semi-conductor. A large amount of calcium fluoride (CaF2) is present in wastewater sludge as a result of the semiconductor manufacturing process. Centrifugal separators are used to recover CaF2 from the process gas used in plasma etching and it is sold to manufacturers of glass ceramics and steel, thus recycled instead of being landfilled. They use special oversized receiver style separators made entirely of stainless steel to maximize efficiency in the smallest footprint possible.

Air compressor systems take our natural air which contains moisture and particulates and condenses it under pressure to be used for drying, blow-off and instrumentation control device applications. When air is compressed the moisture forms condensate which mixes with any particles and tramp lubrication in the system piping. Large systems having complex piping and several low areas or several piping size changes enable build-up of liquid which is eventually swept as a �slug� downstream, reducing the effectiveness of drying processes, contributing to product contamination and damaging sensitive instrumentation � these are all reasons why centrifugal separators are used. Refer to our Air/Liquid separators for compressed air applications for additional information.

Steam Systems

This is another type of application found throughout almost all industries because steam is used for heating, cleaning, atomization, humidification and propulsion. Many variables affect steam quality (the percentage of entrained condensate droplets within the steam). Generally, the further you get away from the boiler, the cooler the steam and more of it converts back to liquid water, which also includes corrosion inhibitor chemicals. Pipe scale and corrosion particles mix with the condensate and can clog or damage components downstream.

The nature of steam and compressed air systems is that they inherently create entrained liquid droplets in their piping, leading to corrosion and quality related issues. When combined with particulates in the piping, contamination, component damage and increased maintenance results. Centrifugal gas/liquid separators will separate droplets and particles larger than 10 microns with 99% efficiency, they are considered self-cleaning and never require maintenance. Physical dimensions of the separator and inlet/outlet orientation, material of construction and overall design confirm to ASME Code. Learn more about steam/condensate separators.

Food Processing

In addition to compressed air and steam system applications, there are many other applications that benefit from gas/liquid separation in food processing. One of the most common applications is to separate vented mist from mixing and tumbling vessels. Food products are sprayed with oils, flavorings, dyes, and sometimes cooled with water and then dried; coatings are controlled with high velocity compressed air or blower �air knives�. These types of processes generate mist which is source of product contamination and can reduce the efficiency of a heating or drying application.

Installing an exhaust head on the vent port of a pressurized mixing vessel helps keep the surrounding environment free from surface contamination, slippery surfaces and breathing in oil mist. In-line gas/liquid separators are used within vent systems in some processes to reduce build-up in ducting or reduce moisture prior to a combustion or gas treatment process.

Power Generation

Large-scale power generation systems heat water into steam which rotates turbine blades at high velocity. These blades are eroded from impacts of fine droplets, contributing to imbalance, which is amplified due to the high RPM of the blades. These turbine systems are very expensive to replace and down time equates to producing less energy, so it is paramount that they control the size and number of droplets through their system.

In addition to requiring high quality steam, many companies have incorporated turbine misting systems to increase the efficiency (horsepower) by as much as 15%. While there are many factors involved in generating a narrow histogram of fine droplets to be evenly dispersed within the intake piping of a turbine, a gas/liquid separator can be used to ensure the droplets exiting the separator are fine enough to pass through the turbine blades without damaging them.

Cogeneration is a type of process which uses biofuel byproducts to reduce raw energy requirements. An example is digester gas, a byproduct of municipal waste water treatment and when properly treated (removing of entrained liquid and particles) it can be used as fuel to reduce the utility costs of the treatment plants' dewatering process.

Petrochemical Industry

Such applications include refineries, natural gas processing, manufacturing of plastics and rubber - essentially products in which petroleum has been refined and used in their making. While we often think of petroleum refined into gasoline, there are actually many byproducts of the refinery process. These byproducts are created by controlling the pressure, temperature and injection of catalysts into liquids and gasses. In refineries there are many processes involving the compression and expansion of hot gasses, injection of chemistry and precipitation of the targeted byproducts. Some of these oils and solvents are used in the manufacturing process of other products.

Natural gas contains water, dirt and other impurities, some extraction methods result in more impurities than others (fracking). While settling tanks can be used to help separate gas from other liquid petroleum products and water, a separator at the wellhead is a compact way to separate entrained impurities larger than 10 microns, eliminating settling tanks which suffer from corrosion and damage from extremely low temperatures. When natural gas is transferred, it is typically under high pressure and thus additional separators are used to minimize corrosion and protect downstream equipment. View our webpage gas/liquid separators for natural gas applications for additional information.

Environmental

Liquids and particles which can be sent to atmosphere or ground are increasingly regulated; the EPA and local government agencies have established guidelines for disposing of industrial waste fluids such as compressor condensate and the tramp oils it may contain

Boiler treatment chemicals are carried-out through rooftop steam vents and can condense locally onto the rooftop itself or perhaps carry-on to nearby property and structures. Such carry-out is a form of pollution and results in an increased use of boiler treatment chemistry to make-up for what was carried out. Using an exhaust head, which is a centrifugal separator sized for atmospheric pressure, you can separate and collect the condensate for proper disposal or re-use.

Electronics Manufacturing

There are many chemical and physical processes required to turn sand into a semi-conductor. A large amount of calcium fluoride (CaF2) is present in wastewater sludge as a result of the semiconductor manufacturing process. Centrifugal separators are used to recover CaF2 from the process gas used in plasma etching and it is sold to manufacturers of glass ceramics and steel, thus recycled instead of being landfilled. They use special oversized receiver style separators made entirely of stainless steel to maximize efficiency in the smallest footprint possible.