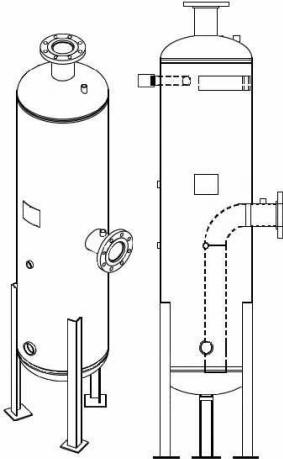

Blowdown Tanks: Steam System Solutions

Steam blow down vessels with ASME code stamp

Blowdown tanks manage steam system pressure safely and efficiently, protecting equipment and meeting ASME standards. Designed to handle blowdown from boilers, these tanks reduce noise and disperse steam effectively. Whether you’re in power generation or industrial processing, find out how our blowdown solutions fit your needs—check specs or sizing tips below.

Blowdown tanks manage steam system pressure safely and efficiently, protecting equipment and meeting ASME standards. Designed to handle blowdown from boilers, these tanks reduce noise and disperse steam effectively. Whether you’re in power generation or industrial processing, find out how our blowdown solutions fit your needs—check specs or sizing tips below.

Boiler blowdown tanks enable elimination of contaminated condensate from within the boiler. All of the dissolved impurities within the water and from the piping system eventually precipitate out in the form of rust and scale which will eventually contribute to component wear and reduce heat transfer efficiency. In addition, keeping the water properly treated is more difficult (expensive) when the water contains a high level of contaminates.

Why Use a Blowdown Tank?

-

Prevents flash steam damage to piping.

-

Quiets exhaust.

-

Applications: boiler rooms, HVAC, manufacturing.

A blowdown tank

enables safe collection of flashed steam and condensate. Whereas a

flash tank is

used to extract low pressure steam and reclaim condensate for reuse,

blowdown tanks are designed to enable extraction or venting of low

pressure steam through an

exhaust head and discharge of the contaminated condensate

once it has cooled sufficiently.

Our blowdown tanks direct condensate below the retention level of the

tank, allowing cooler water remaining from earlier blowdowns to drain

first. The tanks are designed in accordance with ASME Code Section

VIII, Div. 1 and can be ASME Code Stamped. We can also supply the

sealing and blowdown drain valves.