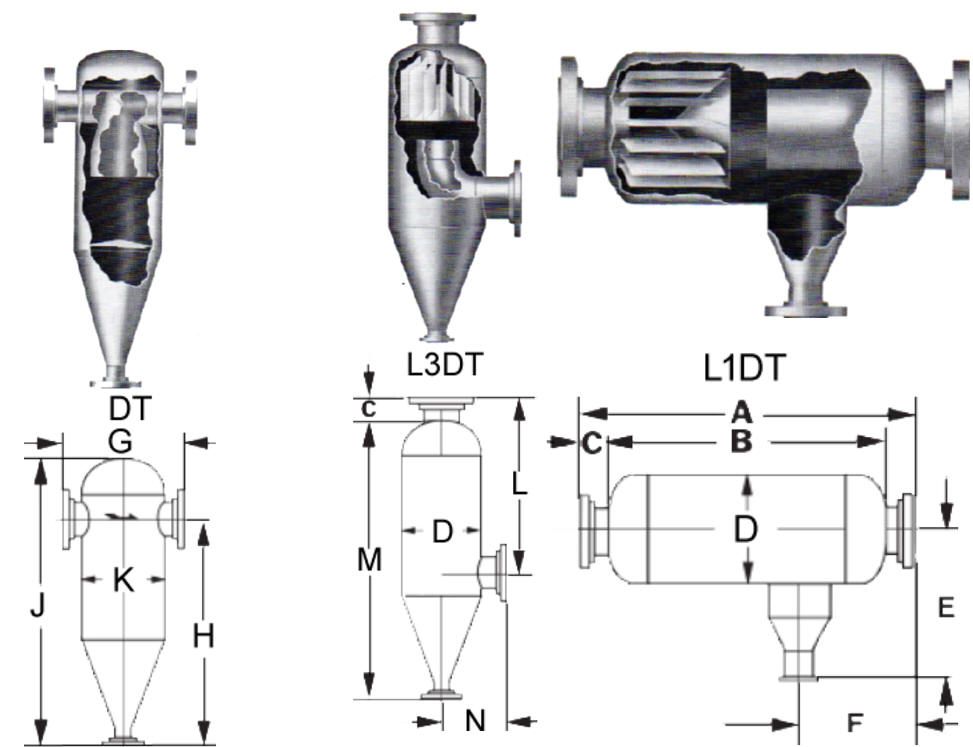

DTL ANTI-CLOGGING GAS-LIQUID SEPARATORS

Droplet separators 99% efficient for droplets >10 microns

The type DTL gas/liquid separators have a modified body designed to drain viscous liquids, sludge and high volumes of particulate matter. Whereas standard type T, L3 and L1S separators have drain ports installed onto dished heads, the type DLT uses a steep angle conical body with an oversized flanged drain port. This makes it easier for slow moving liquids, slurries and particles to exit the drain port of the separator. The most common drainage method is actuating a rotary valve and enabling system pressure to purge the separated material from the body of the vessel. It is also possible to monitor the level of separated material to actuate a valve with pump to positively transfer that material to the next process. DTL separators have been used to recover valuable particulate that would otherwise have been exhausted.