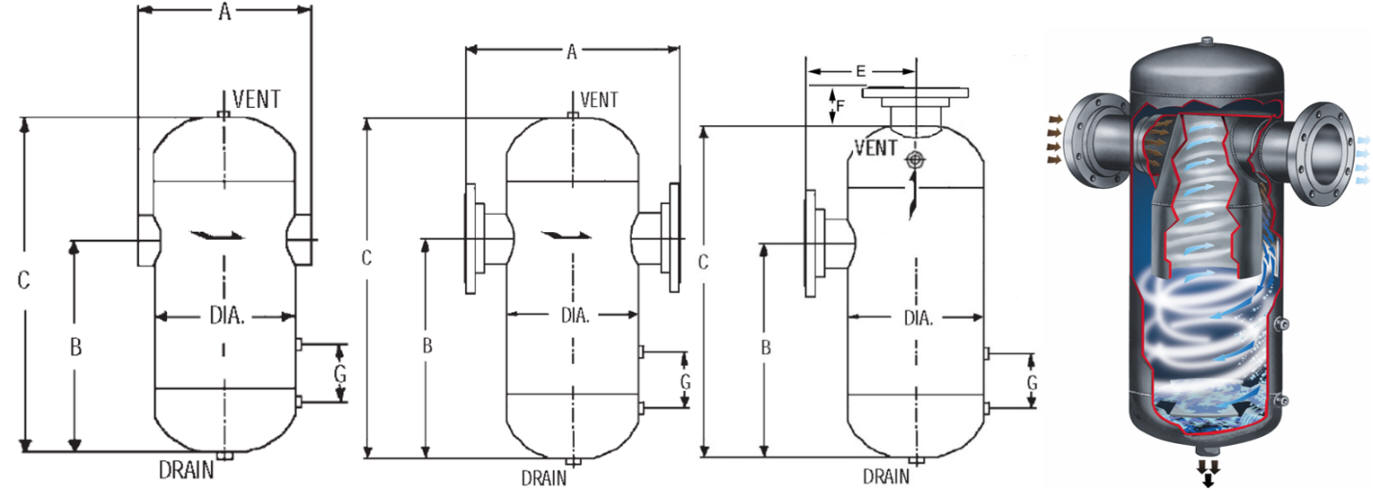

TYPE T GAS-LIQUID SEPARATORS

Droplet separators 99% efficient for droplets >10 microns

Fully welded pressure vessel fabricated to ASME Code Section VIII Division 1 with stamp, has no serviceable/moving components, requires zero maintenance.

Typically manufactured from pipe, they can be fabricated from rolled plate; standard materials include carbon steel, 304L SS and 316L SS although they can be fabricated in other alloys when required. We also offer 1½ through 4” sizes in cast iron, typically less costly then fabricated separators and a lead time from stock to 2 weeks. Customizations include support legs, additional ports and non-flanged connections.

CAST IRON TYPE T AND ST GAS-LIQUID SEPARATORS

Cast iron type T and ST (containing an internal float drain trap) are

inexpensive alternatives for gas/liquid separation when an ASME Code Stamp is

not required and when cast iron material is compatible with the media and

pressure/temperature conditions.

Both T and ST separators separates entrained droplets and particles larger than 10 microns in diameter with 99% efficiency