Exhaust Head Design

Applications for Exhaust heads

Call us at 908.362.9981 to speak with a sales engineer

This

article is the third in a series of articles describing gas/liquid

separation via centrifugal force; it describes a specialized type of

vortex separator referred to as an exhaust head and complements our

articles

Gas/Liquid Separator Designs and

Coalescer Gas/Liquid Separator Designs.

This

article is the third in a series of articles describing gas/liquid

separation via centrifugal force; it describes a specialized type of

vortex separator referred to as an exhaust head and complements our

articles

Gas/Liquid Separator Designs and

Coalescer Gas/Liquid Separator Designs.

Centrifugal

Separation Explained

Vortex separators, commonly referred to

as centrifugal separators, rely on centripetal force to overcome the

inertia associated with droplets and particles larger than 10 microns

such that their trajectory is curved away from the vortex and outlet

nozzle and instead impinge upon the internal structure to coalesce to a

common drain.

Advantages of centrifugal separation

include:

1. high efficiency (99%) removal of entrained

droplets >10 microns

2. reduced vessel size compared to mesh pad and

vane styled separators; directly corresponds to reduced cost

3.

simplicity of design has no serviceable or wearing components; there are

no maintenance requirements.

Exhaust Heads Differ from

In-Line Separators

Whereas an in-line separator has both an

inlet and outlet pipeline connection, exhaust heads only have a pipeline

connection to its inlet as the outlet is open to atmosphere.

This

is a limiting factor relegating exhaust heads to certain types of

applications involving venting of non-hazardous gasses and liquids.

Current exhaust head design is credited to

Mr. Arthur J Filkins and his 1925 patent for “Exhaust head for exhaust

steam pipes”. The application he invented it for, removing entrained

liquid (water droplets, trace lubricants and boiler treatment chemicals)

from steam vent pipes remains the most common application for exhaust

heads.

An exhaust head reduces the carry-out of liquids and

associated contamination, which can be as innocuous as reducing rooftop

icing in cold environments to reclamation of chemistry that otherwise

would be contaminating the surrounding environment. The reduced exit

velocity inherent with centrifugal separator design also corresponds

with reduced projection into the surrounding environment.

Unintended Benefit

Due to the design of centrifugal

or vortex style exhaust heads, the noise associated with high velocity

venting is somewhat reduced. This sometimes leads to confusion between

an exhaust head and vent silencer.

A vent silencer is designed to

reduce the noise associated with venting a pipe to atmosphere due to the

sudden expansion of the gas being vented. This is accomplished by using

sound absorbing materials and creating a reactive section to reduce low

frequency noise. Liquid separation due to the internal geometry of vent

silencers may be considered an unintended benefit.

Thus, exhaust

heads are designed to remove entrained liquid with any noise reduction a

non-engineered “benefit” and vent silencers are designed to reduce

noise; any liquid separation is a non-engineered “benefit”.

To

engineer or maximize both liquid removal and noise reduction would

require installation of an in-line separator prior to a vent silencer.

Exhaust Head Design

Since all of the other

vortex separator models are designed and manufactured in accordance to

ASME Division I, Section VIII and stamped, exhaust heads are

manufactured in-kind however since they are not pressure vessels, they

cannot be code stamped.

Atmospheric pressure is the design

pressure standard for exhaust heads and they are sized to have a ≤ ∆ 0.9

PSI pressure drop. This aspect often leads to confusion of piping design

specifications associated with a given site, as the last piece of

equipment cannot be code stamped and its “maximum pressure” is described

as only 14.7 PSIG even though it has a fully welded design and often

with 150 lb. class flanged connection. The internal welding of the

separation impeller, vortex containment plate, inlet and drain

connections are all in accordance to ASME code simply because that is

the manufacturers standard.

Exhaust

Head Applications

Exhaust

Head Applications

Reduced opacity and projection of vented

steam accomplished by removing droplets larger than 10 microns with 99%

efficiency and reduced exit turbulence. A consequential benefit includes

reduced noise attributed to the both reduced turbulence and an indirect

path to atmosphere. The rooftop and surrounding environment are subject

to less liquid carry-out and the removed condensate may be reclaimed to

reduce chemical and water make-up.

Steam exhaust heads are often

constructed of carbon steel and have a 304SS internal separation

impeller. The inlet connection can be threaded, flanged or butt-weld to

match the corresponding vent pipe. If the environment is corrosive, such

as an off-shore natural gas or oil rig, they can be supplied in 304SS,

316SS or other alloys. For pipeline sizes ≤ 10” we offer cast iron

designs for a significantly reduced cost and lead time compared to

custom fabricated designs.

Air exhaust is another somewhat common

application for exhaust heads. Sometimes there are processes involving

mixing vessels or machining centers which are too numerous to vent

through the rooftop and perhaps cost prohibitive to tie into a

centralized exhaust system.

Whether it is lubricants, steam or

wet air in some localized and contained process, an exhaust head

provides a relatively inexpensive method for removing those entrained

droplets and protecting the surrounding personnel/environment. Such

applications are still typically accommodated by cast iron or fabricated

steel designs, although some food, beverage and biopharmaceutical

applications may require stainless steel construction.

Lifespan of an Exhaust Head

Since exhaust heads are fully

welded or cast and have no moving or otherwise serviceable components,

they have no maintenance requirements and an indeterminate lifespan.

Usually exhaust heads are replaced when the process conditions change,

relegating the existing exhaust head less efficient. If an exhaust head

is unable to drain, the condensate will contribute to oxidation which

can eventually compromise the integrity of the body.

They are

designed such that water from the external environment flows directly to

the exhaust head drain and does not bypass the exhaust head, so even

when not in operation, standing liquid should not be a problem as long

as the drain port remains open and unblocked. When an application is

intermittent and there is concern of birds or other animals nesting

within the exhaust head, we can attach a screen across the outlet to

discourage that from happening.

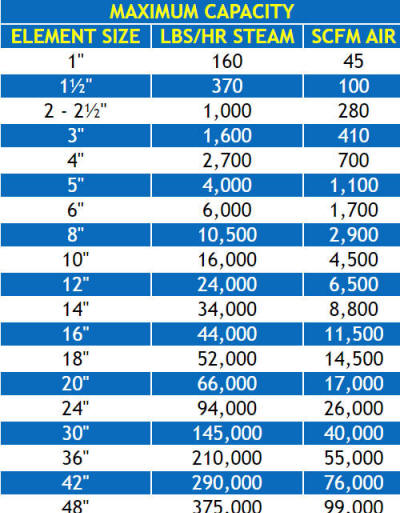

Sizing an Exhaust Head

Sizing an Exhaust Head

As with their inline versions, the physical body of an exhaust head

required for an application (its internal diameter, surface area and

volume) is dictated primarily by the volume of steam or air to separate

and NOT the inlet pipe size. When we refer to a given “size” separator,

we are referring to the maximum corresponding inlet nozzle size that can

be used, but there is no “minimum” size. For example, an application

having a 4” size vent pipe might require a 6” size separator, to which

we can attach a 4” connection to match the intended vent pipe size.

Likewise, a 4” vent pipe might only require a 3” size separator from a

performance perspective, however it would require using a 4” size

separator to match the intended pipeline size.

Our expertise lies

with understanding the applicable design criteria for a given

application and providing detailed proposals for the most cost-effective

design.

Let us know

how

we can assist you with your separation application!