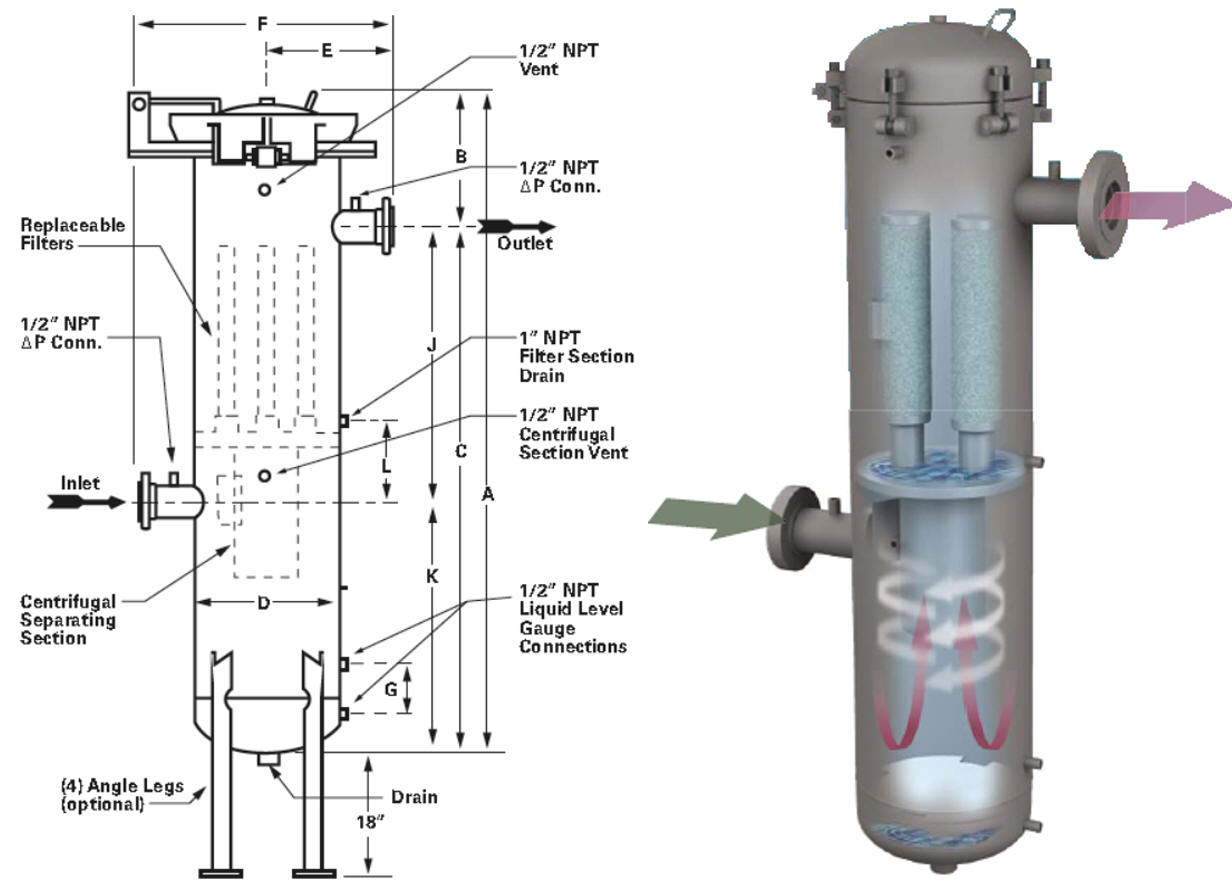

Vortex Mist Separators

Coalescing filter design for droplets as fine as 0.3 microns

![]() TF coalescing

filter separator specifications

TF coalescing

filter separator specifications

Mist

separators remove entrained droplets >5 microns with 99% efficiency. Vortex mist separators are a type of

coalescing

separator using centrifugal force for separation of droplets larger

than 10 microns in the vortex section and droplets as fine as 0.3 microns in

the second, coalescing section.

The process gas

enters into the side of the centrifugal mist separator, forming a low

velocity

centrifugal vortex due to the entry angle, nozzle size and

vessel diameter. The inlet to the mist elimination section is located within the low velocity

(center) portion of the

centrifugal vortex, thus droplets and particles larger than 10 microns

are propelled to the vessel walls where they coalesce to a common drain

under the vortex containment plate (VCP). The VCP prevents

re-entrainment of the separated fluid into the process gas.

The

process gas with droplets finer than 10 microns enter the mist

separation section, consisting of a filter

cartridge manifold. The filter cartridges are made of

epoxy saturated borosilicate microglass fibers. This matrix of fibers

creates a drain channel for each cartridge, thus the fine droplets are coalesced into

larger droplets and drained from the cartridge and back into the

separator body via a common drain port.

The fineness of the droplets removed

is dependent upon the filter cartridge design, which can be as low as

0.3

microns removed with 99.7% efficiency. The body of mist separators

have a chamber cover to enable periodic filter cartridge

replacement which might be required if particulate fouls the filter

cartridge media.

Our article "Coalescer gas/liquid separator designs" explains the mist separator design in detail.